Product Description

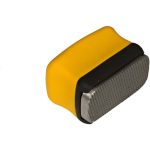

This is a great honing fluid, whether you own a Tormek sharpening system or not (and seriously, if you don’t, and like sharp tools, look into getting one.) This honing compound is used straight on the T-3, T-4, or T-7 leather wheel strop (or the profiled leather honing wheels) to remove burrs and polish tool edges to razor sharpness. Used after the grinding stone, this 3-micron honing compound (approximately 8000 grit) will buff and polish the edges of Tools, Knives, Wood Chisels, Plane Irons, Spoke Shaves, Carving Tools, Lathe Turning Tools, and Scissors. One application should last for 5–10 tools. You can also use this on a stand-alone leather strop if you wish (but again, if you are interested in sharp tools for your workshop, the Tormek water-cooled sharpening systems really can’t be beat.)

From the Manufacturer

The Tormek PA-70 Honing Compound is used straight on the T-3, T-4, T-7 leather wheel strop or the profiled leather honing wheels to remove burrs and polish tool edges to razor sharpness this 3-micron honing compound. Grain averages 3 microns (approximately 8000 grit). This will buff and polish the edge of tools Knives, Wood Chisels, Plane Irons, Spoke Shaves, Carving Tools, Lathe Turning Tools, Knives, and Scissors after using the Tormek Grindstone. One application should last for 5–10 tools. Work the honing compound into the leather. Do not let the compound dry, apply more oil if necessary.

Manoxo business standart

Manoxo business standart

Manoxo express delivery

Manoxo express delivery